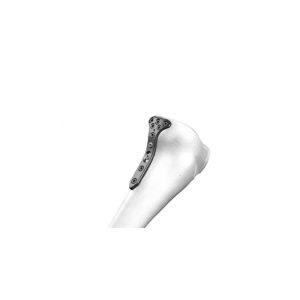

Intramedullary nailing system

proximal femur (INSPF)

- Easy to use, built-in targeting guides to help with k-wire placement

- 2 portal approach to ensure rotational stability intra- and post-operatively

- Lower adjustment screw for controlled dynamics

- Built-in fracture gap closure and fracture compression

All nails are available in left and right versions, with a pre-curvature depending on the length to allow a close anatomical fit to the patient. Short and intermediate nails are indicated for all femoral lengths and as such use an average femoral convexity of 1100 mm.

Dynamics control

The Inferior DyCon® Set Screw anchors into the nail and captures the slot in the lag screw, allowing controlled lateral dynamics and preventing full contact medial migration.

DyCon® Pair of screws

The DyCon® screw pair, consisting of a load-bearing lag screw and a DyCon® adjusting screw mounted below, creates a dynamically controlled force transmission system in the neck and femoral head.

While 5 mm lateral dynamics is standard, this design allows flexible screw movement with an offset from 0 mm (static) to 10 mm (dynamic+).

Static (0mm)

Provides maximum stability without lateral movement, suitable for fractures requiring rigid fixation.

Dynamic (5mm)

It allows up to 5 mm of controlled lateral movement, limiting femoral neck shortening to an area of "no" or "mild" ill effect on hip function.

Dynamic (10mm)

It provides up to 10 mm of movement for improved dynamics, i.e. for complex or unstable fractures that require more compaction to promote bone healing.

Panel technology. ONE technology for all implants. All ITS. plates are made of Grade 2 titanium, while the screws are made of a harder titanium alloy. This allows the plates to have only threadless holes, all of which (with the exception of the elongated holes) accept both non-locking and locking screws.

Similar products

Similar products

-

Flexible Titanium Nail (FTN)

Read more Read more -

Phoenix Proximal Humeral Locking Plate System (PHL PHX)

Read more Read more -

Intramedullary Claw (IMC)

Read more Read more -

Tube Locking System (TLS)

Read more Read more -

Distal anterolateral tibial locking plate (DTL)

Read more Read more -

Flat compression lock plate (SCL)

Read more Read more -

Clavicle Locking Plates System (CLS)

Read more Read more -

Proximal medial tibial locking plate (PROMET)

Read more Read more -

Distal forearm locking plate (DUL)

Read more Read more -

Calcaneal locking plate (CALmi)

Read more Read more -

Cannulated Recon Heel Screw (CRCS)

Read more Read more -

Calcaneal lock plate (CAL)

Read more Read more